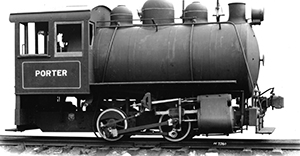

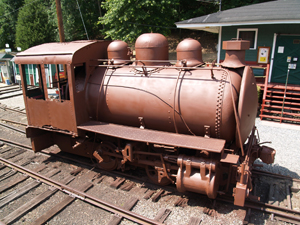

Locomotive No. 7240 was built in February 1937 by the H.K. Porter Co. of Pittsburgh, PA for use at the The Texas Company’s (Texaco) Marcus Hook (PA) Refinery as the plant switching engine. In the early 1960’s, the locomotive was transferred to Texaco’s Bergen Point Refinery in Bayonne, NJ where it continued to provide reliable service.

When Bergen Point closed at the end of the Sixties, the 30-ton locomotive was “stored serviceable” and sat idle through the 1970’s and into the early 1990’s.

After a series of ownership changes, No. 7240 came under the care of Joseph Supor, Jr., founder of J. Supor & Son Trucking & Rigging Company of Harrison, NJ. Before his passing in September 2007, Mr. Supor arranged the donation of No. 7240 to the Whippany Railway Museum.

In 2009, Whippany Railway Museum volunteers restored the diminutive locomotive to it’s original 1937 Texaco appearance.

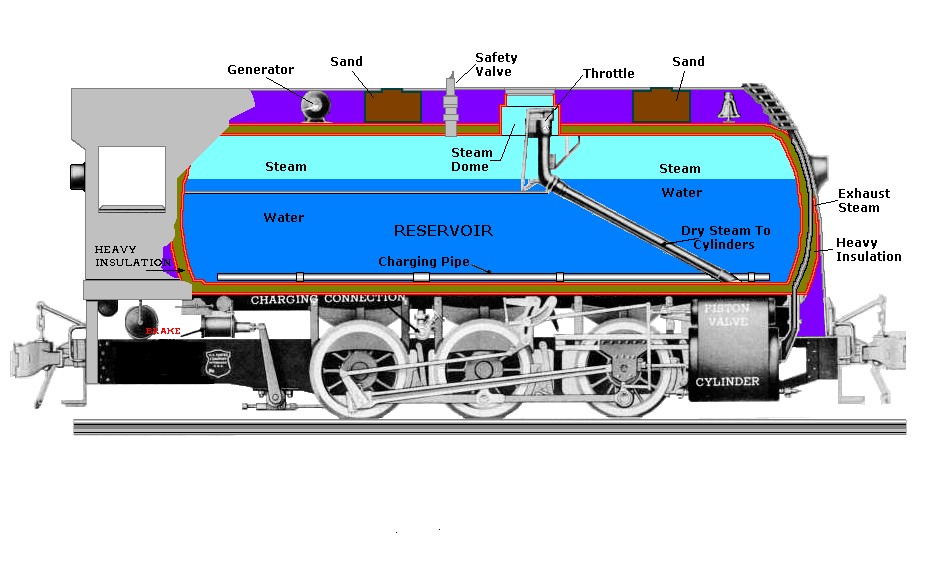

No. 7240 is a very unique form of railroad motive power, being very different from a conventional fire-powered steam engine. More commonly known as a “Fireless Cooker”, it is one of the most remarkable and foolproof locomotive designs devised. A fireless engine is equipped with a large tank or reservoir instead of a boiler and firebox…it carries no fire. This type of engine is essentially a giant thermos bottle lying on its side, with wheels.

In a fireless steam locomotive, in place of a boiler, the locomotive is fitted with a cylindrical tank which is charged with steam and hot water from a stationary plant.

The reservoir / tank stores heat in the form of hot water and steam. Steam is charged into the reservoir at a “Charging Connection”. The time required to take on a full charge varies from ten to thirty minutes depending on the charging pressure and the size of the reservoir.

When the reservoir is fully charged, 85% or more of its volume is filled with hot water and the remainder with steam. When the throttle is opened, and as steam is drawn off and utilized in the cylinders, pressure in the reservoir drops and some of the hot water flashes to steam. This newly-created steam draws its heat of vaporization from the hot water which remains in the liquid state, and in turn, the temperature of that water is reduced. This continues until the temperature of the water drops to the point below which it will no longer vaporize into steam at sufficient pressure to be utilized in the cylinders. The locomotive must then be recharged. One charging, plus several partial charging’s, would be enough to keep a “Fireless Cooker” at work for a full day.

Water in the tank, at charging, would be heated to temperatures of 400 degrees F, with internal tank pressures rising up to 400 psi. The cylinders would operate at pressures of 150 psi.

“Fireless Cookers” were very desirable for service in plants where cleanliness and the elimination of fire hazards were important. They were quite popular in textile mills, agricultural processing plants, chemical industries, gun-powder plants, paper mills, electric-power plants and refineries.

These little switching locomotives were honored as a very relaible and economical form of motive power that gave many decades of faithful service to their owners, and have earned a rightful place in transportation history.